Difference between revisions of "Optimize Asset Utilization"

(→Evaluation) |

|||

| (7 intermediate revisions by the same user not shown) | |||

| Line 21: | Line 21: | ||

== Use Case == | == Use Case == | ||

| + | # RU retrieves technical asset data digitally | ||

| + | # RU provides usage data to Keeper digitally | ||

| + | # RU provides asset faulty technical data to Keeper digitally | ||

| + | # Keeper maintains the technical data for the asset digitally | ||

=== RU retrieves technical asset data digitally === | === RU retrieves technical asset data digitally === | ||

| Line 26: | Line 30: | ||

The retrieval for the wagon asset is described here: | The retrieval for the wagon asset is described here: | ||

[https://rff.models.interconnective.ch/model/latest/index.htm?guid=AC95E364-B010-4992-ADE1-C021509F6361 Rolling Stock Retrieval Workflow] | [https://rff.models.interconnective.ch/model/latest/index.htm?guid=AC95E364-B010-4992-ADE1-C021509F6361 Rolling Stock Retrieval Workflow] | ||

| − | [[File:UC_RollingStockQuery.png]] | + | [[File:UC_RollingStockQuery.png|border|center|800px|RollingStock Query]] |

| − | === RU provides usage data to | + | === RU provides usage data to Keeper digitally === |

When using an asset the RU sends the data digitally to the keeper. | When using an asset the RU sends the data digitally to the keeper. | ||

==== Asset usage ==== | ==== Asset usage ==== | ||

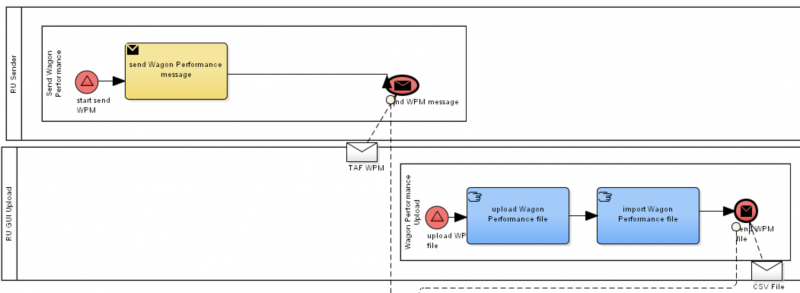

The RU sends the usage data of an asset to the maintaining keeper. | The RU sends the usage data of an asset to the maintaining keeper. | ||

[https://rff.models.interconnective.ch/model/latest/index.htm?guid=2CBF2F55-228C-4b43-B267-E8B721A08C39 Wagon Performance Workflow] | [https://rff.models.interconnective.ch/model/latest/index.htm?guid=2CBF2F55-228C-4b43-B267-E8B721A08C39 Wagon Performance Workflow] | ||

| − | [[File:UC_WagonPerformance.png]] | + | [[File:UC_WagonPerformance.png|border|center|800px|Wagon Performance]] |

==== Asset faulty technical data ==== | ==== Asset faulty technical data ==== | ||

The RU also sends any faulty technical asset data to the keeper as input for correction. | The RU also sends any faulty technical asset data to the keeper as input for correction. | ||

| Line 39: | Line 43: | ||

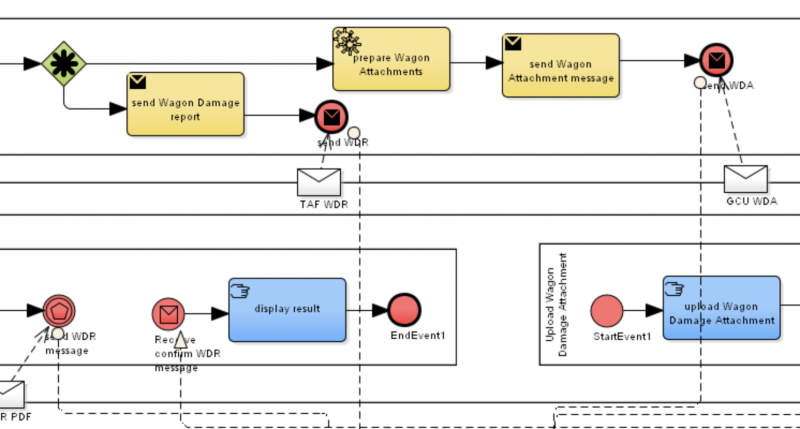

The RU reports any damage that he detects during a technical check back to the keeper. | The RU reports any damage that he detects during a technical check back to the keeper. | ||

[https://rff.models.interconnective.ch/model/latest/index.htm?guid=905C6D1D-6A67-4acd-A43E-A04CDB2C3043 Wagon Damage Workflow] | [https://rff.models.interconnective.ch/model/latest/index.htm?guid=905C6D1D-6A67-4acd-A43E-A04CDB2C3043 Wagon Damage Workflow] | ||

| − | [[File:UC_WagonDamageReport.png]] | + | [[File:UC_WagonDamageReport.png|border|center|800px|Wagon Damage]] |

| Line 70: | Line 74: | ||

* #105 | * #105 | ||

| + | The topic is linked to the [[Damage Information]] smart service. | ||

| + | The second one covers a part of this extensive service. | ||

== Planned Steps == | == Planned Steps == | ||

| + | Roland Berger consultants have elaborated a study about asset management in 2016. | ||

| + | [https://www.rolandberger.com/de/Media/Roland-Berger-Studie-Eisenbahnbranche-sollte-Wartung-und-Instandhaltung-weiter.html Asset Management study] | ||

| + | == Evaluation == | ||

| + | |||

| + | |||

| + | * Tom Thijs commented 27 Apr 2021 13:01 | ||

| + | For Optimize Asset Utilization, shouldn't we include next overhaul date? | ||

| + | -> That should be part of the technical data set provided by the Keeper. | ||

| − | + | * Frank Kschonsak commented on 25 June 2021 | |

| + | This used to be use cases in the “VDV” project (“elektr. Lok- und Zugakte”); collecting all relevant operational data for the vehicles for the moment “train is running” or “will be running” | ||

| + | Assumption is, that all stakeholders deliver current data, like the temporary “owner” of a loco feeds the “platform” with the latest error-codes or workshop/maintenance repairs | ||

| + | Discussions so far showed, that the business model for this is difficult to establish so it can be guaranteed, that the information-pool is valid. | ||

| + | Another problem is, that only parts of master data is currently online in certain databases like “RSRD2”. Also even “RSRD2” is currently maintained only by one part of the wagon holders. A complete system to correct wagon data (and receive the milage of the vehicle might be useful. | ||

| + | * Answer: RSDS data for wagons should be available from GCU and its GCU Broker service. | ||

Latest revision as of 10:25, 6 July 2021

Description

The focus for this smart service is on digital specification of assets and its components, both software and hardware. This data can be provided by the manufacturer and the keeper/manager for this asset. It includes the evolvement of the asset (lifecycle) and its usage data.

The asset can be a

- Movable

- Locomotive

- Wagon

- Intermodal Unit

- Immovable

- Location (facility, point, station, yard)

- Section (segment, route)

The technical data of an asset includes the technical specification of:

- the type of asset

- the modification and enhancement of the individual instance

- additional features of the individual instance

- the actual restrictions and limitations of the individual instance

It covers both the hardware and software features of the asset.

Use Case

- RU retrieves technical asset data digitally

- RU provides usage data to Keeper digitally

- RU provides asset faulty technical data to Keeper digitally

- Keeper maintains the technical data for the asset digitally

RU retrieves technical asset data digitally

The RU retrieves digitally the necessary technical data for the asset. The retrieval for the wagon asset is described here: Rolling Stock Retrieval Workflow

RU provides usage data to Keeper digitally

When using an asset the RU sends the data digitally to the keeper.

Asset usage

The RU sends the usage data of an asset to the maintaining keeper. Wagon Performance Workflow

Asset faulty technical data

The RU also sends any faulty technical asset data to the keeper as input for correction.

Asset damage

The RU reports any damage that he detects during a technical check back to the keeper. Wagon Damage Workflow

Asset Keeper maintains the technical data digitally

The asset keeper updates and maintains actively the technical data of the asset.

Preconditions

- Standardized digital asset specification (legal)

- Legally binding to digital representation (legal)

Basic Services

Dependencies

This topic depends on the bottom up capabilities

Location

- #1 CRD Location

- #2 CRD

- #5 CRD

- #6 CRD

Wagon

- #36

- #39

- #42

- #43

- #44

- #45

- #46

- #105

The topic is linked to the Damage Information smart service. The second one covers a part of this extensive service.

Planned Steps

Roland Berger consultants have elaborated a study about asset management in 2016. Asset Management study

Evaluation

- Tom Thijs commented 27 Apr 2021 13:01

For Optimize Asset Utilization, shouldn't we include next overhaul date? -> That should be part of the technical data set provided by the Keeper.

- Frank Kschonsak commented on 25 June 2021

This used to be use cases in the “VDV” project (“elektr. Lok- und Zugakte”); collecting all relevant operational data for the vehicles for the moment “train is running” or “will be running” Assumption is, that all stakeholders deliver current data, like the temporary “owner” of a loco feeds the “platform” with the latest error-codes or workshop/maintenance repairs Discussions so far showed, that the business model for this is difficult to establish so it can be guaranteed, that the information-pool is valid. Another problem is, that only parts of master data is currently online in certain databases like “RSRD2”. Also even “RSRD2” is currently maintained only by one part of the wagon holders. A complete system to correct wagon data (and receive the milage of the vehicle might be useful.

- Answer: RSDS data for wagons should be available from GCU and its GCU Broker service.