Difference between revisions of "Optimize Asset Utilization"

m |

|||

| Line 26: | Line 26: | ||

The retrieval for the wagon asset is described here: | The retrieval for the wagon asset is described here: | ||

[https://rff.models.interconnective.ch/model/latest/index.htm?guid=AC95E364-B010-4992-ADE1-C021509F6361 Rolling Stock Retrieval Workflow] | [https://rff.models.interconnective.ch/model/latest/index.htm?guid=AC95E364-B010-4992-ADE1-C021509F6361 Rolling Stock Retrieval Workflow] | ||

| − | [[File:UC_RollingStockQuery.png]] | + | [[File:UC_RollingStockQuery.png|border|center|800px|RollingStock Query]] |

=== RU provides usage data to keeper digitally === | === RU provides usage data to keeper digitally === | ||

| Line 33: | Line 33: | ||

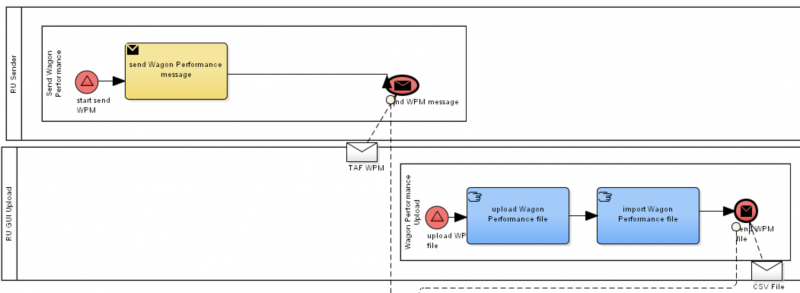

The RU sends the usage data of an asset to the maintaining keeper. | The RU sends the usage data of an asset to the maintaining keeper. | ||

[https://rff.models.interconnective.ch/model/latest/index.htm?guid=2CBF2F55-228C-4b43-B267-E8B721A08C39 Wagon Performance Workflow] | [https://rff.models.interconnective.ch/model/latest/index.htm?guid=2CBF2F55-228C-4b43-B267-E8B721A08C39 Wagon Performance Workflow] | ||

| − | [[File:UC_WagonPerformance.png]] | + | [[File:UC_WagonPerformance.png|border|center|800px|Wagon Performance]] |

==== Asset faulty technical data ==== | ==== Asset faulty technical data ==== | ||

The RU also sends any faulty technical asset data to the keeper as input for correction. | The RU also sends any faulty technical asset data to the keeper as input for correction. | ||

| Line 39: | Line 39: | ||

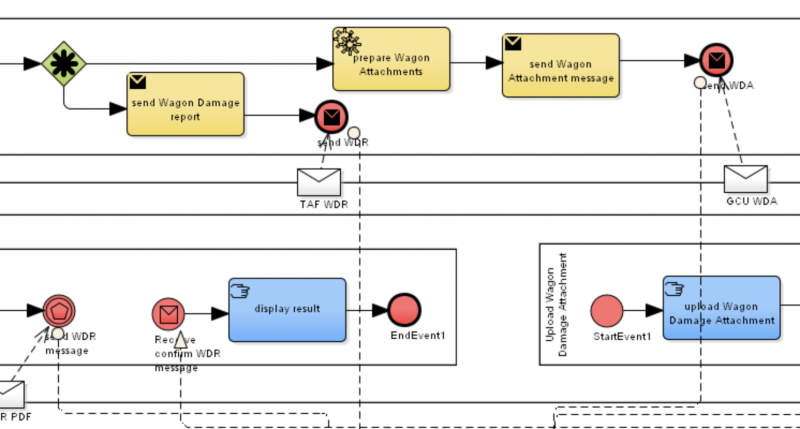

The RU reports any damage that he detects during a technical check back to the keeper. | The RU reports any damage that he detects during a technical check back to the keeper. | ||

[https://rff.models.interconnective.ch/model/latest/index.htm?guid=905C6D1D-6A67-4acd-A43E-A04CDB2C3043 Wagon Damage Workflow] | [https://rff.models.interconnective.ch/model/latest/index.htm?guid=905C6D1D-6A67-4acd-A43E-A04CDB2C3043 Wagon Damage Workflow] | ||

| − | [[File:UC_WagonDamageReport.png]] | + | [[File:UC_WagonDamageReport.png|border|center|800px|Wagon Damage]] |

Revision as of 11:22, 11 March 2021

Description

The focus for this smart service is on digital specification of assets and its components, both software and hardware. This data can be provided by the manufacturer and the keeper/manager for this asset. It includes the evolvement of the asset (lifecycle) and its usage data.

The asset can be a

- Movable

- Locomotive

- Wagon

- Intermodal Unit

- Immovable

- Location (facility, point, station, yard)

- Section (segment, route)

The technical data of an asset includes the technical specification of:

- the type of asset

- the modification and enhancement of the individual instance

- additional features of the individual instance

- the actual restrictions and limitations of the individual instance

It covers both the hardware and software features of the asset.

Use Case

RU retrieves technical asset data digitally

The RU retrieves digitally the necessary technical data for the asset. The retrieval for the wagon asset is described here: Rolling Stock Retrieval Workflow

RU provides usage data to keeper digitally

When using an asset the RU sends the data digitally to the keeper.

Asset usage

The RU sends the usage data of an asset to the maintaining keeper. Wagon Performance Workflow

Asset faulty technical data

The RU also sends any faulty technical asset data to the keeper as input for correction.

Asset damage

The RU reports any damage that he detects during a technical check back to the keeper. Wagon Damage Workflow

Asset Keeper maintains the technical data digitally

The asset keeper updates and maintains actively the technical data of the asset.

Preconditions

- Standardized digital asset specification (legal)

- Legally binding to digital representation (legal)

Basic Services

Dependencies

This topic depends on the bottom up capabilities

Location

- #1 CRD Location

- #2 CRD

- #5 CRD

- #6 CRD

Wagon

- #36

- #39

- #42

- #43

- #44

- #45

- #46

- #105